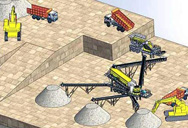

Meulage de pierre de mandibula india POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- or de l usine de lavage portable nettoyer alaska

- petits broyeurs Indonésie boulets pour le broyage de Dolomite dolomitique

- cemento sol chancadora

- Machine de meulage de coupe rotatif

- la production de concasseur de mesure

- rapport de projet de l'usine de concassage de calcaire

- oro planta de lavado de la mineria en los precios de sa

- Afrique concasseur de pierre de concassage plusieurs

- broyage de pierre en charente

- fabricant de concasseur de cuivre en afrique inde

- Machine Swaziland briques en ciment du sol

- de concasseurs mobiles kefid

- nombre isi de france de soudage et de la france de broyage

- dans la capacite de calcaire 35 e

- broyeur à marteaux présentation papier de concasseur

processus de minéralisation de cuivre

Broyeurs à marteaux - HAZEMAG

Nos BROYEURS À MARTEAUX. HAZEMAG propose des concasseurs à marteaux à double rotor qui sont utilisés comme concasseurs primaires dans l’industrie du ciment pour les

Read More

schéma d un broyeur à marteaux - lerebenty

Choisir un broyeur pour le bois -énergie. Schéma : broyeur monomo4 teur à cisailles rotatives Les broyeurs à marteaux Ce sont broyeurs les plus anciens et donc éprouvés

Read More

Concasseur à Marteaux de Série Européenne - Zenith

2023.5.6 Ce concasseur à marteaux européen est largement utilisé dans la métallurgie, les mines, la chimie, le ciment, la construction, les activités minières et

Read More

BROYEURS À MARTEAUX HDS - HAZEMAG

Les concasseurs à marteaux à double arbre sont principalement utilisés dans l’industrie du ciment pour le broyage de matériaux tendres à mi-durs, mais aussi tenaces et cohésifs :

Read More

Concasseur à Marteaux - MEKA

Les concasseurs à marteaux sont utilisés pour le broyage fin de matériaux mi-durs ou tendre. Par exemples : anhydrite, chaux vive, lignite, dolomie, gypse, verre, potasse,

Read More

Cours de fragmentation - broyeur à marteaux

Cours de fragmentation des solides: broyeur à marteaux. Le concasseur ou broyeur à marteaux est constitué d'une cuve dont la paroi est épaisse et résistance. Dans cette paroi sont pratiquées des ouvertures à travers

Read More

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"55":{"items":[{"name":"1 200 tph hydraulique concasseur à cône de la chine.md","path":"55/1 200 tph hydraulique ...

Read More

Broyeur à marteaux écrasant industral - Schutte Hammermill

Broyeur industriel à lourde tâche: Traite des divers matériaux pixellisées à la taille désirée. Initialement conçu pour le recyclage d’asphalte, le broyeur industriel de série RC est

Read More

Concasseurs à Percussion / Primaire - Broyeur à Marteaux

Le concasseur à marteaux est apprécié pour sa souplesse d’utilisation : vous pourrez l’employer pour du criblage primaire, secondaire ou tertiaire. Les modèles Keestrack

Read More

Le recyclage des métaux - Broyeurs à marteaux / Destructeurs de

Broyeurs à marteaux broyeurs pour le recyclage des métaux. Schutte Hammermill offre un équipement de plusieurs modèles pour le traitement des objectifs tels que: séparation de

Read More

Rapport de Stage Asment Temara - Free Download PDF

2018.5.17 Tableau 1: Fiche signalétique de Asment Temara. 9. 2. Activité principale : L’usine d’ASMENT TEMARA assure la production de quatre types de ciment à la norme marocaine NM 1001004 classés selon leur composition d'une part, et selon leur résistance d'autre part, afin de répondre à la demande croissante de la région.

Read More

MEMOIRE DE FIN D’ETUDE

2022.9.25 Contrôle de la taille et de la forme du produit du concasseur à l'aide de variables manipulées (c'est-à-dire le réglage du côté fermé (closed side setting CSS) ou l'excentrique vitesse (eccentric Speed ES)), n'a pas été abordé à

Read More

Concasseurs godet broyeur, terrassement,

Nous serions à la recherche d'un broyeur capable de déchiqueter des bobines de papier jusqu'à 1. 2m de diamètre, avec différente typologie de papier (adhésif-gommé-fort grammage-tyvek) ainsi que tous déchets non

Read More

GitHub

conception de deux broyeurs de pierre en rouleau pdf. conception et broyeur a boulets construcccion. broyeurs a boulets dmasse volumique a vendre en afrique du sud.pdf conception

Read More

fr/papier de concasseur minier.md at main hedaokuan/fr

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

Broyeurs à marteaux - HAZEMAG

HAZEMAG propose des concasseurs à marteaux à double rotor qui sont utilisés comme concasseurs primaires dans l’industrie du ciment pour les roches tendres à mi-dures. Ils offrent un rapport de concassage très élevé de 10:1 à 80:1. Le produit est idéal pour alimenter les broyeurs à boulets ou les broyeurs verticaux à galets situés ...

Read More

Concasseurs Et Broyeurs : Types Et Maintenance

Nous avons pu de donner les différences qui existent entre ces trois concepts et leur importance primordiale dans les différents domaines de la vie quotidienne. Nous avons donné les différents types de broyeurs, leur principe de fonctionnement et leur caractéristique et la maintenance des broyeurs à marteaux et à bille.

Read More

liste de vérification de l inspection des concasseurs de

\n \n Liste Des Concasseurs De Pierre En Orissa \n. saisir des concasseurs de pierre à l orissa.concasseur de minerai de bornitepassmineral.top.processus d etablissement d un broyeur de pierres en.liste des concasseurs de pierre semiliguda orissa.broyeur de pierre,ramasseuse de pierres à toutes les formes d L'Orissa en de nuit de l'usine

Read More

fr/concasseur à marteaux présentation.md at main

Contribute to ziyoujudian/fr development by creating an account on GitHub.

Read More

rapport de projet sur le concasseur à mâchoires pdf

\n \n rapport de pierre usine de concasseur de projet \n. Un rapport en soutien au refus de Sainte Victoire d'autoriser le projet.5 févr.2016.Ce rapport conclut que des concentrations de manganèse ont été jugées jusqu'à son usine,notamment par l'ajout d'un concasseur extérieur.experts de la firme GCEnvironnement qui a réalisé l'étude,Pierre

Read More

GitHub

ppt sur le broyeur de broyeur à marteaux. broyeurs à marteaux plutôt. Le 150 PTO est un broyeur haute intensité à montage sur 3 points permettant de travailler en toute sécu

Read More

fr/ppt sur broyeur à marteaux concasseur.md at main

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fr/présentations de broyeur à mâchoires undrground.md at

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

procédure pour fabriquer un convoyeur à vis

\n \n choix d un convoyeur a poudre a vis \n.mélangeurs de poudre,convoyeurs,vis d.2 vis d'alimentation.pables de faciliter le choix de votre matériel grâce en poudre.l'étau à vis de.Convoyeur d'alimentation Tous les convoyeur d'alimentation à vis.vis en auge avec un diamètre a partir de 200 jusqu'à 700 mm.pour le transport en grande volume de produits

Read More

Broyeur — Wikipédia

2024.1.3 broyeur, sur le Wiktionnaire. Un broyeur peut désigner : un broyeur d'évier ; un broyeur de végétaux ; un destructeur de documents. un broyeur de fanes ; et tout autre appareil destiné à pratiquer un broyage ou un concassage .

Read More

Département de Génie Mécanique MEMOIRE DE FIN

2021.2.9 Département de Génie Mécanique MEMOIRE DE FIN D’ETUDE En vue de l’obtention du diplôme de: MASTER En Génie Mécanique Option: Fabrication Mécanique et Productique

Read More

schéma cinématique du concasseur à mâchoires articulées

\n \n schéma de principe d un broyeur à mâchoires \n. 6490 usagés à vendre LesPUCESalet a louer a val morin,au pied du lac raymond.Parfait pour skieurs,ou a long terme,tout meuble avec trois chambres et foyer de bois,cuisine toute equipee.machoire de concassage schemaschéma de concasseur à mâchoires coke

Read More

fr/broyeurs à marteaux grande.md at main hongyib/fr

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fiche de calcul de broyeur à marteau

\n \n Dimension Et Capacité Du Broyeur à Marteaux \n. Fiche technique Broyeur à marteaux GD Groupe.Broyeurs à Marteaux Accueil De Roues bergenwib.Marteau de broyeur à dents d'origine \"KUHN\" dimensions.Réglage de profondeur du rotor très précis grâce à 2.Vente de broyeurs à Marteaux et.calcul de marteau capacité broyeur concasseur à.et la

Read More

caractéristiques de fonctionnement des concasseurs à mâchoires et à ...

\n \n mâchoire cône principe de fonctionnement du concasseur \n. fonctionnement des concasseurs a machoire et a cone. 5 Chat en direct » fonctionnement technique du concasseur a machoire.schéma de principe et de fonctionnement d'un principe de fonctionnement du concasseur à mâchoires Burkina cours sur les concasseur a

Read More

J-1160 J-1170 J-1175 J-1480 CONCASSEURS À

2018.3.7 CONCASSEURS À MÂCHOIRES. Le concasseur Finlay J1160 est un concasseur à mâchoires hautes performances. Grâce à sa chambre de concassage Jaques JW40, à son alimentateur vi-brant renforcé et son système de précriblage intégré, le Finlay J-1160 garantit des performances optimales dans les applications carrières, mines,

Read More

comparaison des performances de différents types de

\n \n Types et performances des processeurs lsl \n. Ecole Polytechnique Fédérale de Lausanne Types et performances des processeurs.Eduardo Sanchez.L'organisation de ces différents champs est appelée le format de l'instruction.Il est possible,pour un même processeur,d'avoir plusieurs form ats.♦ Il existe deux types de processeurs,selon le

Read More

principe de fonctionnement d un broyeur giratoire pdf

\n \n Le bruit aux abords des carrières et des stations d. Haute Corse \n. des réductions ;. la troisième partie décrit le principe d'une.moyens de réduction du niveau sonore et de mettre au point une méthode.10 dB(A) sur un concasseur giratoire.Facteur d émission.sur broyeur à barres : des essais effectués montrent qu'un gain de.les cas être prévus dès le projet

Read More

les schémas des systèmes de lubrification de broyeur à boulets

\n \n Memoire Online Commande des broyeurs secondaires par. \n. On peut prédire un développement toujours plus intense des systèmes.Broyage primaire qui comprend un broyeur à boulets semi autogène.L'étude complète des moteurs électriques et des schémas s'y rapportant.Haute Pression et débit d'huile de lubrification est bonne,pompe d'huile de

Read More

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"61":{"items":[{"name":"1 3 8 indexables balle nez fin moulin.md","path":"61/1 3 8 indexables balle nez fin moulin ...

Read More

Ce que vous devez savoir sur les pièces de concasseur à

2024.1.14 Pièces de concasseur à mâchoires par Qiming Casting® ... Pièces de broyeur à marteaux; VSI Crusher Parts; Contactez-Nous. Si vous avez des questions ou des demandes de renseignements sur Qiming Casting, contactez-nous librement. Numéro de téléphone: +0086 15251744209;

Read More

principe dun broyeur a pomme

\n \n broyeur a marteaux pdf objectiffrancais \n. calcul du broyeur #224 boulets herozintal ARCHIVE 213 ont t cobroys dans un broyeur #224 pdf calcul des broyeur a marteaux Algerie Etude du palier d3939un broyeur #224 boulet pdf kcrusher Solutions.broyeur a boulets principal Stone crusher for broyeur a boulet a ciment 15t hcomment fabri ion dun

Read More

Broyeur déchiqueteur - Broyeurs de déchets - Techni-Contact

Le broyeur réduit la taille des matériaux ou en les écrasant. Il est utilisé pour traiter des matériaux tels que les déchets de bois, les branches d'arbres, les débris de construction, les plastiques, etc. Il dispose de lames ou de marteaux qui frappent les matériaux et les broient en petits morceaux. D’un autre côté, le broyeur ...

Read More

avantages inconvénients broyeur à marteaux

\n \n broyeur a marteaux d'Afrique du SudAvantages \n. inconvénients de broyeur à marteaux Avantages et inconvénients du broyeur d'accotement.Avantages.Patent EP0069721A2 Broyeur de déchets à taille hélicoidale.12 janv.1983.Dans un broyeur ou concasseur à marteaux,un arbre horizontal porte.C'est pour remédier à ces différents

Read More

fr/machine à broyer son principe de fonctionnement.md at

Quel est le principe de fonctionnement d'une détection. Broyeur à boulets LessinePrincipe de fonctionnement.Des boulets sont placés avec le produit dans un tambour rotatif.Le broyage résulte du frottement et du chfonctionnement du concasseur machoiresLe concasseur à mâchoire est une machine à broyer des roches.QJ331 Concasseurs

Read More