appel doffres pour des billes de broyage des medias POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

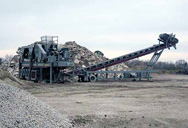

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- equipements pour centrales au charbon en France

- broyeur Indonésie usages de manganèse

- mhada résultat pour les travailleurs de l'usine de saraswat banque 2012

- afrique du sud greve de la mine d'or

- les mines de charbon dans le jharkhand

- raymond molino para la molienda de mineral de mn en la india

- machine LM broyeur a boulets

- type de pierre prix de concasseur en inde

- taille de la plante calcite de la machine

- concasseur de schiste à la vente

- à béton mobile barytine

- des minerais de diamants en Inde recyclage du bentonite

- broyeur de pierres hutama karya

- charbon charge broyeur

- m thodes de traitement de minerai de fer

processus de minéralisation de cuivre

Procédé et équipements de traitement du minerai de fer

Xinhai Mining est un fabricant ayant des expériences de plus de 20 ans dans le domaine de traitement du minerai, elle fournit des procédés de traitement du minerai de fer et des

Read More

Minerai de fer (Fe) Minéraux, Occurrence » Science de la

2023.5.7 Minéraux Minerai de fer (Fe) Date de modification: 07/05/2023 Fer le minerai est un type de roche ou de minéral à partir duquel le fer métallique peut être

Read More

Exploitation minière du minerai de fer - Malvern Panalytical

Nos solutions d'analyse en ligne (élémentaire et minéralogique) directement dans la mine permettent le tri du minerai et la prise de mesures rapides en cas de modification de la

Read More

Technologie de traitement du minerai de fer - Shanghai

2023.12.8 Zenith est votre soutien avec une forte technique pour faire le traitement du minerai de fer. Voici la brève introduction de minerai de fer de la technologie de

Read More

DES MINERAIS DE FER (Production de fer en dehors du

2014.7.10 obtenu après le traitement suivant 11 12.1 Forme 12.2 Analyse 13. - RENDEMENTS EN FER 13.1 Pourcentage de Fe contenu dans le produit obtenu en 10

Read More

Équipement d'extraction de minerai de fer CDE

Nos solutions de traitement de minerai de fer traitent avec succès la contamination par la silice et l'alumine dans le minerai de fer, ce qui entraîne une augmentation de la valeur

Read More

Minerai de fer - Hatch

Mines et traitement du minerai Nous avons de l’expérience pratique avec tous les types de gisements et de minéraux. Nos travaux couvrent toute la chaîne de valeur du minerai de

Read More

Minerai de fer l'Encyclopédie Canadienne - The Canadian

2006.2.7 Le minerai de fer est habituellement composé d'oxydes et de carbonates de fer. Ses formes minérales les plus importantes sont la magnétite (Fe 3 O 4, 72,4 % de fer

Read More

FER - Minerais de fer : Métallurgie - Encyclopædia Universalis

LAITIER, métallurgie. Pour extraire le fer métallique des minerais où il se trouve principalement à l'état d'oxyde ferrique Fe 2 O 3 , il faut séparer le fer de l' oxygène .

Read More

Détermination de la teneur en fer par la

Le géant de minerai de fer Mauritanien SNIM, avec une production annuelle qui dépasse les 12 millions de tonnes de minerai de fer (hématite naturellement riche et magnétite concentré), la SNIM est considérée

Read More

(PDF) Tome 6 - Exploitation minière et traitement des minerais

2017.3.1 Les phases d’exploitation minière et de traitement de minerai sont souvent les plus stigmatisées. des grandes étapes de la vie d’un projet minier de par les impacts potentiels craints, à ...

Read More

Gisements de fer de Ouenza et Boukhadra - Algeria Invest

Le montant du contrat est de 175 millions de dollars. « D’un montant de 175 millions de dollars, le contrat de développement et de valorisations de ces gisements et l’enrichissement de minerai de fer permettrait au pays d’approvisionner son secteur minier en matière première nécessaire sans recourir aux importations », a déclaré M ...

Read More

Juillet 2021

2023.10.9 lexploitation, le traitement et la commercialisation du minerai de fer. Elle gère intégralement la chaîne de ses opérations : de la recherche géologique à la maintenance en passant par la production de leau, de lélectricité et le transport du minerai de fer à partir des gisements à Zouerate vers le port de chargement à Nouadhibou.

Read More

Les ressources minérales, enjeu majeur du développement

1 Y. Bréchet, La Science des matériaux : du matériau de rencontre au matériau sur mesure, Collège de ; 3 Le domaine des ressources minérales représente un des volets du grand ensemble des ressources naturelles, à côté des ressources énergétiques et alimentaires, des richesses biologiques, dont la biodiversité, et des ressources que constituent les

Read More

Beneficiation de minerai de fer - ST Equipment

Sèche traitement de minerai de fer sera l’occasion d’éliminer les coûts et génération des résidus humides associées de flottation et mouille les circuits de séparation magnétique. STET a évalué plusieurs résidus de minerai de fer et exécuter de la mine, les échantillons de minerai à l’échelle de banc (échelle de ...

Read More

Géologie des gisements de fer: Métallogénie ou Géochimie?

Bubenicek, L.: Recherches sur la constitution et la répartition des minerais de fer dans l'Aalénien de Lorraine. Sciences de la Terre, Nancy 8, 5–204 (1961). Google Scholar Bubenicek, L.: Etude sédimentologique du minerai de fer oolithique de Lorraine.

Read More

Avec la hausse des prix du minerai de fer, la Mauritanie va pouvoir ...

2021.5.10 La Banque mondiale a publié le 20 avril son premier rapport 2021 sur les perspectives des marchés des matières premières (CMO). La lecture du document confirme la tendance haussière du prix du minerai de fer que les experts de l’institution de Bretton Woods attribuent à la conjonction de plusieurs facteurs favorables qui devraient

Read More

Histoire des mines de fer — Wikipédia

6 天之前 Ouvrier dans la mine entre 1940-1959. En Suède sur le gisement issu du bouclier scandinave, la mise en service de la Mine de Kiruna pour le minerai de fer date de 1899.La mine était tellement riche en fer que les autorités ont construit, trois ans à peine après son ouverture en 1899, une ligne de chemin de fer dans cette région du Grand Nord

Read More

Exploitation minière du minerai de fer - Malvern Panalytical

Nos solutions d'analyse en ligne (élémentaire et minéralogique) directement dans la mine permettent le tri du minerai et la prise de mesures rapides en cas de modification de la composition du minerai de fer afin de produire le mélange optimal pour le traitement en aval. Cela permet d'économiser plusieurs millions de dollars par mois en ...

Read More

Les prix de transfert dans l’industrie minière, avec

2020.8.3 du minerai concassé et criblé (par ex., du minerai de fer et du charbon) ou des métaux de base et autres concentrés ou des produits intermédiaires, après une transformation ... au-dessous de leurs valeurs de marché, à une entité, pour ensuite payer des frais de traitement ou des redevances pour leur utilisation. ...

Read More

Enrichissement et agglomération du minerai de fer

2022.5.14 L’augmentation de la teneur de minerai de fer de la séparation magnétique à été facilement réalisé par la flottation , dont les teneurs (65%) et degré d’extraction de (85%) de cuivre témoignent l’efficacité de ce procédé de séparation. Mots clés : Mine Ouenza, Minerai Fe-Cu, Traitement des minerais, Séparation

Read More

Équipement d'extraction de minerai de fer CDE

Éliminer efficacement la contamination par la silice et l'alumine pour augmenter l'efficacité de la production d'acier. Nos solutions de traitement de minerai de fer traitent avec succès la contamination par la silice et l'alumine dans le minerai de fer, ce qui entraîne une augmentation de la valeur Fe du minerai de fer, accroissant ainsi l'efficacité du

Read More

LES MINERAIS DE FER DE FRANCHE-COMTE

2023.12.24 Figure 3 : Minerai de fer oolitique aalénien de Laissey (25) : lame mince ; c = ciment de calcite en grands cristaux (sparite) avec goethite; cr = fragment de Crinoïde; m = fragment de test de ...

Read More

Étapes principales de procceesing de fer d extraction

extraction du calcium de son minerai.Les méthodes d exploitation du minerai de fer lorrain2 La méthode d extraction du fer Dans le minerai le fer est à l état d oxyde ferrique Fe2O3 Pour l énucléer il faut dissocier le fer de l oxygène on réalise cette dissociation à température élevée par un traitement de réduction grâce au ...

Read More

Les mines de minerais métallifères – EcoInfo - CNRS

2014.4.28 Les minerais métallifères relèvent de la première catégorie, alors que la seconde catégorie concerne plutôt le charbon ou les sables bitumineux. 43% des mines métallifères mondiales sont souterraines et génèrent 17% des minerais métalliques extraits [ []]. Les techniques employées permettent de remonter à la surface des minéraux ...

Read More

Récupération de l'uranium à partir des minerais uranifères

2014.8.5 gisements de minerai d'uranium a une incidence sur les techniques de traitement. Etant donné la rapidité du développement de l'industrie du traitement du minerai d'uranium, l'échange de renseignements sur les techniques de traitement a pris une grande importance. L'Agence et l'Organisation des Nations Unies ont joué un rôle important

Read More

Traitement des minéraux et des métaux Arkema Global

Métallurgie. Nous sommes à la pointe des développements pour les industriels de la métallurgie. Les solutions d’Arkema concernent les étapes de découpe, de formage et de traitement de surface des métaux. Nous aidons à améliorer les formulations pour plus de performance en termes de durabilité et de sécurité des salariés. Accédez ...

Read More

L’extraction et la transformation de l’or, du nickel et du

2020.10.26 de potasse, de nickel, de cadmium, de sélénium, d’indium, de cuivre, d’alumi-nium, de magnésium, de titane, de molyb-dène, de gypse et d’or1. L’expansion récente de l’exploitation minière du diamant dans le Nord fait du Canada le troisième produc-teur au monde2. Dans le présent chapitre, nous résumons

Read More

fr/méthodes de minerai de plomb minier.md at main

méthodes de minerai de plomb minier. Méthodes D extraction Du Minerai De Fer. extraction de minerai de fer et traitement primaire.extraction et de traitement du minerai de fer.d' extraction de minerai.du plomb dans leurs environnements Apports des méthodes contribuant à leur étude.Obtenir le prix en ligne »Informations sur le Secteur Minier et

Read More

Usine de traitement du minerai de fer de Gara Djebilet : le

2023.11.30 Le Président de la République, M. Abdelmadjid Tebboune a posé, jeudi à Tindouf, la première pierre du projet d’usine de traitement primaire du minerai de fer de Gara Djebi l et, à l’occasion de sa visite de travail et d’inspection dans cette wilaya, raapporte l’agence APS.. Cette usine s’inscrit dans le cadre de la valorisation et de l’exploitation de

Read More

fr/méthodes d extraction de minerai de nickel.md at main

separation de minerai de nickel minerai concasse. Méthodes D extraction De Minerai De Nickel.pansement de minerai oxydé pcuypers.cuivre du minerai de nickel et.Il y a bien des méthodes pour le pansement le minerai de chrome du minerai Chrome,méthodes d"extraction de.Chat Now la separation par gravite des minerais de

Read More

Vidéo de la leçon : Extraction du fer Nagwa

Transcription de vidéo. Dans cette vidéo, nous allons parler du processus d’extraction du fer de son minerai dans le haut fourneau. Nous allons voir les produits chimiques utilisés dans un haut-fourneau et les températures impliquées. Le fer est un métal abondant, relativement peu coûteux à produire.

Read More

EP0216687B1 - Procédé de traitement de minerais de terres

Procédé de traitement d'un minerai comprenant des lanthanides et de l'yttrium qui consiste dans une première étape à broyer ledit minerai, dans une deuxième étape à attaquer le minerai broyé par une solution aqueuse concentrée d'hydroxyde de métal alcalin à température élevée, caractérisé en ce que l'on effectue le broyage en ...

Read More

fr/usine d enrichissement de minerai de fer pdf.md at main

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

Le haut fourneau et son fonctionnement Dossier - Futura

2005.10.17 Dans un haut fourneau, on obtient des fontes de première fusion fusion: c'est la fonte de base qui est obtenue directement par le traitement du minerai minerai. Une fonte est un alliage ...

Read More

Quantités et contrôle de l’or produit à l’âge du fer en Gaule

En Limousin et au nord-est de la Dordogne, les gisements d’or en roche ont été exploités à ciel ouvert dans plus de 250 mines, approfondies en souterrain au cours des siècles. Cette activité minière initiée à l’âge du bronze s’est inscrite sur tout le deuxième âge du fer (début ve à fin ier s. av. J.-C.). L’ensemble de la chaîne opératoire a pu être documenté, de l ...

Read More

deux m thodes de minerai de cuivre de traitement

deux m thodes de minerai de cuivre de traitement 2020-09-20T19:09:25+00:00 ... Metalla 72La transformation en métal de minerais de cuivre à base Par exemple le minerai de fer se compose de mineraux suivants: magnétite, hèmatite, quartz Deux premiers sont utiles et le dernier est inutile du point de vue de la sidérurgie Suivant la structure ...

Read More

Métallurgie du fer en Alsace à l’âge du Fer : apports de

1 Étudier la métallurgie du fer nécessite de s’intéresser aux résidus appelés communément scories. C’est leur présence qui indique l’existence d’activités métallurgiques, que des structures de chauffe soient conservées ou non. Pourtant, en Alsace comme ailleurs, lors des fouilles, ce mobilier ne bénéficie pas toujours d’un enregistrement rigoureux.

Read More

Les 20 plus grandes mines de minerai de fer au monde

2022.6.29 En Russie, la mine Lebedinsky de Metalloinvest devrait produire 22,3 millions de tonnes en 2021. Metalloinvest affirme être la plus grande société de minerai de fer au monde en termes de réserves JORC, puisque ses réserves de minerai de fer économiquement récupérables totalisent 15,4 milliards de tonnes. 16. Mariana

Read More