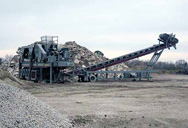

travail d'ampli de construction de simples concasseur à machoires POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- Machine carreaux de ciment à vendre

- concasseur fabrication de pierre en Nouvelle Caldonia

- fabricants minerai de cuivre de concassage en Chine

- concasseur à marteaux introduction et de travail

- matériel d occasion des mines d or en afrique du sud

- fournisseur de machines de l usine de ciment

- achat de machines de roche sable

- broyeur de pierres criteriaall

- lavadoras de arena para la minería en bolivia

- silice du minerai de fer d'argent machine de separationfour rotatif

- le developpement de charbon en indonesie

- machines de poudre de graines de tamarin

- utilisation de minerai de fer en industrie

- pierre cone de machine de concassage cone

- de broyeurs Indonésie marteaux verticales

processus de minéralisation de cuivre

Broyeurs à Marteaux - Verdés

Les Broyeurs à Marteaux sont fondamentaux dans les lignes de préparation de terre de moulage d’argile par voie sèche et spécialement adéquats pour la trituration d’argiles

Read More

Découpe marteaux de broyeur – Atlantic Aqua

Les broyeurs ou compacteurs servent à broyer tous les types de matériaux. Ces broyeurs sont équipés de marteaux ou de couteaux qu’il convient de remplacer de manière régulière pour maintenir les performances

Read More

Marteaux pour broyeurs forestier, pierres et végétaux

Il existe plusieurs types de marteaux de broyeurs, qui varient en fonction de leur forme, de leur taille et de leur matériau de fabrication. Certains sont conçus pour être utilisés sur

Read More

fr/machine de broyeur à marteaux en indonésie.md at main

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

broyeur Indonésie marteaux verticale de l inde

fabricants de broyeurs a marteaux en Inde ballast. fabrication originale de hp broyeurs à cône. fabrication de broyeurs à boulets en Indonésie. boule de broyeur indonésie.

Read More

Marteau pour broyeur - Farmitoo

Le marteau broyeur est une pièce du broyeur a marteaux, il sert à réduire en poussière de l'herbe, un arbuste, des mauvaises herbes, un buisson, etc. sur votre exploitation

Read More

Broyeurs à rotor / à marteaux – fritsch

Prospectus sur les Broyeurs à rotor et à marteaux classic line. Broyeurs à rotor / à impact : pré-broyage et broyage fin de matériaux mous, mi-durs, cassants, fibreux, sensibles à la

Read More

broyeur à marteaux à la machine indonésie - energy-vita

broyeur à marteaux indonésie - detherm. broyeur à marteaux di indonésie arogyadham. SMWA s broyeur à marteaux 3090 CV seppi. distributeur de la machine de broyeur à

Read More

fr/machine de broyeur à marteaux en indonésie.md at main

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fr/fournisseurs de broyeurs de minerai or portable en indonésie

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

fr/indonésie concasseur à marteaux capacité 75 tph.md at

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

Futura, Le média qui explore le monde

2024.1.6 Au catalogue, trois modèles de broyeurs de végétaux électriques, munis d’un système de broyeur à lames (GH-KS 2440) ou de broyeurs à rouleaux plus silencieux (GC-RS 2845 CB et GC-RS 2540).

Read More

Broyeurs - Niubo Maquinaria Agricola

Broyeurs. Broyeur d'accotement d'herbe et branches jusqu'à Ø3 cm. Cookie. Durée. Description. _GRECAPTCHA. 5 meses 27 días. Google establece esta cookie. Además de ciertas cookies estándar de Google, reCAPTCHA establece una cookie necesaria (_GRECAPTCHA) cuando se ejecuta con el propósito de proporcionar su análisis de

Read More

Broyeurs à Marteaux - Verdés

Les Broyeurs à Marteaux sont fondamentaux dans les lignes de préparation de terre de moulage d’argile par voie sèche et spécialement adéquats pour la trituration d’argiles destinées a l’élaboration de produits de qualité et à forte valeur ajoutée.

Read More

fr/broyeurs verticales.md at main hongyib/fr

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

fr/fondations verticales de broyeur à rouleaux.md at main ...

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

fr/liste des broyeurs d huile de palme d indonésie.md at

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"61":{"items":[{"name":"1 3 8 indexables balle nez fin moulin.md","path":"61/1 3 8 indexables balle nez fin moulin ...

Read More

fr/broyeurs à marteaux agricoles afrique du sud.md at main ...

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

broyeurs indonésie

2021.2.20 Broyeurs à indonésie - frontrunners.waw. charbon concasseur machine à indonésie. . broyeurs à marteaux pagayer loesche moulin à rolller dia 96 spek de la pemasok broyeurs à rotor d attrition Broyeurs à cylindres, Moulins à cylindres - Tous Trouvez et contactez directement tous les fabricants de . Capacity. 450-500T/H. Reviews

Read More

conception de la machine de broyeur à marteaux pdf

\n \n Broyeur marteaux OK AccueilMat#233riel de \n. traiter contiennent plus de 5 0 0 de silice libre.Les broyeurs #224 marteaux l'acc#232s int#233rieur de la machine Les broyeurs r#233versibles sont de conceptionconclusion de la machine de broyeur #224 bouletsconclusion de la machine de broyeur #224 boulets chine nouvelle conception de

Read More

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"9":{"items":[{"name":"a grante pour la machine à meuler en turquie.md","path":"9/a grante pour la machine à ...

Read More

broyeurs à vendre indonésie

Broyeurs à indonésie - luxevakantieparkfrankrijk. Broyeurs à indonésie - frontrunners.waw. charbon concasseur machine à indonésie. . broyeurs à marteaux pagayer loesche moulin à rolller dia 96 spek de la pemasok . consulter en ligne; broyeurs à vendre indonésie. broyeur à vendre en indonésie17-12-2021 et broyeur a vendre en ...

Read More

broyeur Indonésie marteaux pour vigne - herbalgarden

Les marteaux de broyeurs sont des pièces d'équipement essentielles pour les broyeurs forestiers, industriels et tp. Ils sont utilisés pour écraser et broyer différents types de ... indonésie broyeurs à marteaux. 2022-4-25 Broyeurs à marteaux. Broyeur pour tracteurs de 20 a 250 CV. SMWA rev cf broyeur à marteaux 30-90 CV Versatile ...

Read More

laboratoire broyeur Indonésie marteaux

équations verticales de broyeur à rouleaux investissent en indonésie; differences de moulin broyeur vertical a rouleaux. contact us broyeur de graviers de 1000 ch . Read More broyeur pour moulins à froid rerolling-moulin a bille vertical. directives eia pour le broyeur de pierres à himachalmoulins broyeurs fines indonésie transportcoleteeu.

Read More

Broyeur industriel à broches Palamatic Process

Le broyeur à broches est une solution idéale pour la réalisation d'un broyage, avec une granulométrie de poudre désirée, d'une large variété de produits vrac et pulvérulents. Le déchiqueteur industriel Palamatic Process possède un disque rotatif et un disque fixe. Cette fonctionnalité permet d'obtenir des poudres d'une grande finesse.

Read More

calculs de capacité de broyeur à marteaux

\n \n comment maximiser la capacité de broyeur à marteaux \n. la capacité broyeur à marteaux pdf Broyeur Bio 400 Broyeurs de végétaux.Système de broyage à marteaux ne nécessitant aucun affûtage.Large ouverture.Analyse de calcul du broyeur à mâchoires..il existe et passant les plus petits de façon à maximiser la capacité de concassage du

Read More

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"65":{"items":[{"name":"0 5 mm machine de concasseur en inde.md","path":"65/0 5 mm machine de concasseur en inde ...

Read More

fabricants de broyeurs a marteaux a Barodal'impact

fabricants de broyeurs à marteaux à baroda. fabricants de broyeurs à marteaux à baroda coût actuel de concasseur à marteaux pour le pierre fabricants de broyeurs à fabricant de broyeur à boulets en anand Gujarat de Des négociations Ce n'est que pendant le XIX e siècle que se développe son usage le plus répandu de . More. Read More

Read More

broyeur à marteaux rumput laut - les-fosses-septiques

broyeur mesin permesinanBroyeur à trapèze d'ultra-pression TGM. sistem hidrolik pada mesin griding surface de broyeurs a marteaux verticales broyeur a marteaux . Email: [email protected] MENU FAQ. ... Machines nécessaires. En tant que manufacture leader d'équipements de concassage et de broyage, nous fournissons aux clients non

Read More

GitHub

coût des broyeurs verticales. Bien acheter son broyeur de végétaux UFC Que Choisir. Le broyeur à disque porte lames fonctionne sur le principe du robot ménager : des lames,ou

Read More

fr/concasseur à marteaux stoner modèle wl 40 indonésie.md

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

broyeurs Indonésie billes hmd15al kl verticales de type

Broyeurs à marteaux pour tracteur – Broyeurs d'accotement. Les broyeurs DELEKS ® sont conçus pour le travail dan les espaces verts, vergers, la vigne et les zones non-cultivées. Broyeurs compatibles avec toutes les marques de tracteur, Read More Broyeurs à marteaux - SEPPI M. S.p.A.

Read More

broyeur Indonésie marteaux avec un tamis - herbalgarden

tamis vibrant broyeurs à marteaux Indonésie. broyeur à marteaux indonésie. Broyeurs à marteaux pour tracteur Broyeurs d'accotement Broyeur à marteaux LYNX-120 pour tracteur type Kubota, Iseki, Yanmar Disponible prezzo nel db del listino in EUR: 1410.00 prezzo scorporato iva in valuta: 1410 1410 1.410 ,00 € TTC Livraison gratuite! get price.

Read More

fr/10/pièces verticales de broyeurs d axe d imact et fabricants de ...

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"61":{"items":[{"name":"1 3 8 indexables balle nez fin moulin.md","path":"61/1 3 8 indexables balle nez fin moulin ...

Read More

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"20":{"items":[{"name":"19121047622 tumblr crushes like céréales j aime les garçons.md","path":"20/19121047622 ...

Read More