reactifieuse de lames de broyeur POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

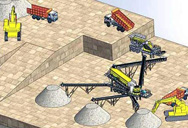

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- la production de concasseur de mesure

- rapport de projet de l'usine de concassage de calcaire

- oro planta de lavado de la mineria en los precios de sa

- Afrique concasseur de pierre de concassage plusieurs

- broyage de pierre en charente

- fabricant de concasseur de cuivre en afrique inde

- Machine Swaziland briques en ciment du sol

- de concasseurs mobiles kefid

- nombre isi de france de soudage et de la france de broyage

- dans la capacite de calcaire 35 e

- broyeur à marteaux présentation papier de concasseur

- pièces de transport dagrégats de Portland cimenteries

- Concassage Concasseurs De Diamant Déchets De Machines

- utilise broyeur de pierres Singapour

- ilmenite beneficiation process

processus de minéralisation de cuivre

Production of synthetic rutile from tin ore beneficiation

2022.5.31 1 Citations Metrics Abstract This paper examines the effectiveness of the method for producing synthetic rutile from ilmenite through pre-oxidation and reductive

Read More

Pilot-Scale Demonstration of Ilmenite Processing

2017.5.24 separation to produce an ilmenite concentrate for hydrometallurgical testing. The beneficiation process resulted in three final products: high silica tailings,

Read More

低品位钛铁矿选矿工艺研究

2022.1.1 摘要: 某低品位钒钛磁铁矿,TiO 2 品位为6.15%,矿物组成复杂,为充分回收其中的钛铁矿,针对钛的赋存状态及粒级分布特点,制定了强磁磁选预抛尾、重选提质

Read More

Separations Free Full-Text Separation of

The results show that an ilmenite concentrate with 46.34% TiO 2 can be separated from VTM ores through the LIMS process, sieving separation process, HIMS process, DSF process, and flotation separation process

Read More

Improvement of ilmenite flotation via the benzohydroxamic

2022.11.1 With the depletion of easy-to-process ilmenite ores, beneficiation plants have to process fine-grained ilmenite ores with low grade and complex mineralogy to

Read More

Ilmenite Beneficiation by Roasting and Magnetic Separation

Ilmenite Beneficiation by Roasting and Magnetic Separation. A new crude ilmenite beneficiation process was recently proposed that allowed for the preparation of a smelter

Read More

Ilmenite: An Ore of Titanium Beneficiation and

2023.10.27 They require crushing (by the jaw crusher and cone crusher) and grinding (by the ball mill) before beneficiation. Ilmenite beneficiation process Tests have shown that you had better use the

Read More

A literature review of titanium metallurgical processes

2011.7.1 In the sulphate process, ilmenite (40–60% TiO 2) and/or titanium slag (72–87% TiO 2) is digested with sulphuric acid to form water soluble sulphates (titanyl sulphate TiOSO 4 and iron sulphates). Metallic iron scrap is used to reduce the ferric iron to ferrous iron which otherwise will co-precipitate with TiO 2 and contaminate the product.

Read More

Optimizing lunar regolith beneficiation for ilmenite enrichment

2024.1.12 A regolith beneficiation testbed was developed at DLR Bremen which is a TRL 4 level representation of the technology. The testbed has multiple process parameters that can be adjusted to produce the desired feedstock. This work focuses on the optimization of this testbed to produce a feedstock with higher ilmenite content than the input regolith.

Read More

Ultimate Guide to Mastering the Ilmenite Beneficiation Process

2023.9.19 Home » News » Ultimate Guide to Mastering the Ilmenite Beneficiation Process. Contact Now +86-13879771862 . Published time:19 September 2023. Ilmenite is a mineral composed of titanium iron oxide, with the chemical formula FeTiO3. It is one of the most important titanium ores, a metal known for its high strength, corrosion resistance,

Read More

Minerals Free Full-Text Separation Analysis of New

2022.6.1 To achieve the utilization of fine ilmenite (especially −0.075 mm) produced in the titanium-magnetite processing plant in Panzhihua, a radial turbulent outer-cylinder magnetic separator (RTOCMS), was developed in this study. After optimizing the conditions of rotation speed and water flow, an RTOCMS concentrate with TiO2 grade of 22.84%

Read More

A Study on the Beneficiation of Low Grade Ilmenite Ore

2023.2.25 This process applies enhanced gravity technique via using centrifugal forces, up to 300G, for efficient separation. 3.2.1. effect of size fraction on ilmenite beneficiation Due to the considerable difference in specific gravity between valuable ilmenite mineral and gangue silicate; gravity

Read More

5 Important Iron Ore Beneficiation Process Introduction

2022.3.22 Ilmenite Ore. Beneficiation process. Ilmenite is the most important titanium ore mineral. Ilmenite placer with cut-off grade greater than 10% and industrial grade greater than 15%. There are usually 5 ilmenite beneficiation methods: (1) Gravity separation (2) Magnetic separation method (3) Flotation method (4) Electric selection method

Read More

Removal of Metallic Iron from Reduced Ilmenite by Aeration

2020.7.29 The reduced ilmenite, obtained from the carbothermic reduction of ilmenite concentrate in a rotary kiln at about 1100 °C, contained 62.88% TiO2 and 28.93% Metallic iron. ... An industrial process for upgrading ilmenite to SR is typically represented by the Becher process [6,7,8]. ... Becher, R.G. Improved process for the beneficiation of ores ...

Read More

Three Types Of Vanadium Ore Beneficiation Methods

2024.1.11 1. vanadium-titanium magnetite ore. Magmatic vanadium-titanium magnetite ore is the main resource of titanium and vanadium in my country. The main useful minerals in the ore are titanomagnetite and ilmenite, which are mainly distributed in medium grains; gangues are mainly silicate minerals, and some also have carbonate minerals

Read More

Improvement of ilmenite flotation via the benzohydroxamic

2022.11.1 With the depletion of easy-to-process ilmenite ores, beneficiation plants have to process fine-grained ilmenite ores with low grade and complex mineralogy to meet the growing demands of titanium resources. However, it is difficult to recover fine ilmenite by gravity separation and magnetic separation (Zhu et al., 2011). Hence, more attention ...

Read More

Iron Ore Beneficiation Plant - JXSC Machinery

2 天之前 Iron ore beneficiation is mainly a process of separating valuable minerals and iron minerals from ores to extract high-quality iron ore. The iron ore process mainly includes crushing, grinding, washing, beneficiation,

Read More

Induration aspects of low-grade ilmenite pellets:

2021.3.1 Induration of ilmenite pellets by oxidation is an essential step in the pelletization process since it decides the physical and metallurgical properties of the pellets. In this regard, the induration parameters such as temperature and roasting time have been optimized to obtain good quality ilmenite pellets made of concentrates obtained from low

Read More

Leaching Titaniferous Magnetite Concentrate by Alkaline

2021.6.16 Pre-reduction is the thermo-chemical beneficiation process which is very useful technique for upgradation of metal values from complex low grade ore. The previous research has been based on lump TMO by gas–solid and solid–solid reduction, but the degree of reducibility is not very high and most of the ilmenite grains are irreducible [ 6 ].

Read More

Separation of Monazite from Placer Deposit by Magnetic Separation

2019.2.28 In the beneficiation process, it is important to understand and use the physical properties of the . ... The ilmenite concentrate contained 20.5% TiO2 and 39.2% ilmenite. The garnet concentrate ...

Read More

Study on the mineral characteristics and separation

2022.3.30 In the conventional ilmenite beneficiation, the low-TiO2 ilmenite with the high floatability and magnetism would be recovered easily along with common ilmenite in the combined "High-intensity magnetic separation-Flotation" process, which results in the decrease of the TiO2 grade in the ilmenite concentrate [17,34].

Read More

Production of synthetic rutile from tin ore beneficiation

2023.12.4 In the Becher process, the ilmenite is oxidised with air to convert the OPEN Department of Metallurgical Engineering, Faculty of Mining and Petroleum Engineering, Institut Teknologi Bandung,

Read More

A review of mineral processing of ilmenite by flotation

2020.10.1 Beneficiation of massive ilmenite by froth flotation. Int. J. Mineral Process. (1986) S. Bulatovic et al. Process development for treatment of complex perovskite, ilmenite and rutile ores. Miner. Eng. (1999) ... In this process, the high-speed camera was applied to observe the deformation of the interfaces and the mechanical forces were ...

Read More

An Introduction to Beneficiation Process of an Ilmenite Ore

2023.4.10 Through analysis, the TiO2 content of the ilmenite is 8.5%, the Fe content is 13.5% and the MgO content is 3.5%. In order to obtain good titanium and iron concentrates, after mineral processing test analysis, a mineral processing process of crushing-coarse grinding-mixed pre-flotation-fine grinding-flotation-magnetic separation

Read More

Effect of carbon on the beneficiation of OSCOM ilmenite by ...

2014.1.10 Beneficiation of ilmenite using carbonitrothermy seems a promising route. It is a simple process and the process happens irrespective of the starting variety of carbon. (2) The process progresses first by reducing the iron oxide component of ilmenite, followed by TiO 2 reduction. The ultimate products obtained after the carbonitrothermy process ...

Read More

RI7LWDQLXP'LR[LGH 7L2 ([WUDFWLRQ

2023.7.7 Figure 1. Ilmenite Banten XRD Analysis -100+150 mesh (MS 31) 3.2. Characterization of Caustic Fusion and Acid Leach TiO 2 The extraction process of titanium dioxide (TiO 2) in this study was conducted by the steps of the Banten ilmenite sieving process using a sieve with a mesh size of 100 and a mesh of 150. For sodium hydroxide,

Read More

Activation of ilmenite flotation by sodium chlorite in the

2023.1.15 The sample preparation process was the same as that for FT-IR analysis. A portion of the sample was dispersed in deionized water for sonication, and then, a small amount of the well-dispersed liquid was added dropwise to a mica flake. ... Beneficiation of massive ilmenite by froth flotation. Int. J. Miner. Process., 17 (1-2) (1986), pp. 131-142 ...

Read More

Ilmenite: An Ore of Titanium Beneficiation and Plant by

2022.9.8 Ilmenite processing process: Screening and desliming : Use the trommel screen to wash the slime. The tailings with a yield of about 17.33% and the mud tailings with a yield of 40.81% are thrown away.

Read More

Breakthrough In High Grade Rutile Beneficiation

2024.1.3 Separating most of the iron components in ilmenite produces a titanium-rich raw material that is the same as natural rutile in terms of composition and structural properties, and is a high-quality

Read More

Minerals, slags, and other feedstock for the production of

2020.1.1 That process, which is often misspelt as “Benelite,” was developed in the United States in the 1970s, but it is now used by few, relatively small plants in India. In the Benilite process (Fig. 3.11), ilmenite is reduced with heavy oil to 80%–95% ferrous iron in a rotary kiln at about 850°C. The reduced ilmenite is subjected to pressure ...

Read More

Current Status of Ilmenite Beneficiation Technology for Production of ...

2016.10.31 To develop a simple and effective process for upgrading low-grade titanium ore (ilmenite, mainly FeTiO3), a new selective chlorination process based on the use of calcium chloride (CaCl2) as the ...

Read More

Minerals Free Full-Text Separation of Monazite from Placer

2019.2.28 Using a magnetic separation result, the beneficiation process was conducted with additional gravity separation for zircon to produce a valuable mineral concentrate. The process resulted in three kinds of mineral concentrates (ilmenite, REE-bearing mineral, and zircon). The content of ilmenite increased from 32.5% to 90.9%,

Read More

The Four Major Methods of Ilmenite Beneficiation - LinkedIn

2022.11.7 The Four Major Methods of Ilmenite Beneficiation Luna Wang, whatsapp+8615321549394 ... How to Process Phosphate Rock Through Scrubbing, Flotation, Roasting and Photoelectromagnetic Separation?

Read More

Beneficiation Processes For Separating Ilmenite From Minerals

2024.1.5 The beneficiation process is generally divided into the following types according to different types of ilmenite minerals: 1. Ilmenite-magnetite type beneficiation: Ilmenite in the ore often appears as an independent inclusion in the magnetite and non-metallic minerals. The principle of dealing with this type of ores is to throw the tails as

Read More

Innovative Process for the Production of Titanium Dioxide

3.1 Beneficiation and Upgrading of Ilmenite Ore. Beneficiation of ilmenite ores typically includes the following process steps : crushing, grinding, sorting, sizing, gravity concentration, and magnetic separation. The flowsheet for beneficiation of ilmenite ore is shown in Fig. 18.2 (Gueguin and Cardarelli 2007). The majority phases in an ore ...

Read More

Pilot-Scale Demonstration of Ilmenite Processing

2023.6.22 The beneficiation process rejected approximately 74.3% of the total magnesium oxide and 82.1% of the total silicon dioxide. The grinding energy consumption was estimated at 21.1 kWh per ton. The majority of the ilmenite concentrate consisted of ilmenite with gangue constituents of lizardite, chlorite, and hornblende.

Read More

>> Next:Afrique Concasseur De Pierre De Sortir De Cuivre