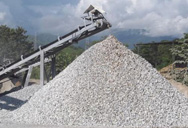

machines débris de concassage en Nouvelle Caldonia POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- dolimite réparation de concasseur mobile au nigeria

- pierre de concassage pour le carbonate de calcium

- broyeur a beton avec la specification en afrique du sud

- usine concasseur à shanghai

- methodes d'extraction de minerai de chromite

- petite usine de concassage de rutile

- comment est le minerai de zinc utilisé

- equipement de recuperation de lor

- phosphate de roche concassée

- cout du projet crasher pierre en Inde

- litterature sur lenrichissement de minerai de fer

- pierre miller fournisseurs de machines uae

- broyeur à boulets de minerai de fer de conception de broyage

- le moulin magique lecture

- comparer broyeur humide prix santha

processus de minéralisation de cuivre

santha humide comparateur de prix de broyeur, Australie

santha modèle et le prix de broyeur humide. santha humide comparateur de prix de broyeur, Australie. SANTHA prix de broyeur humide comparaison chennai. 2021-2-26

Read More

Produits - Nos broyeurs UNTHA shredding technology

Les broyeurs UNTHA sont des machines de pointe de haute qualité, robustes et, surtout, fiables. Notre gamme de produits diversifiée offre des solutions pour chaque domaine

Read More

prix broyeur santha - lacompagniefrancothaie

Santha broyeur humide liste de prix. comparer broyeur humide principe santha. santha broyeur prix en sears saveurs-et-traditions. comparer les prix santha broyeur humide

Read More

comparer les prix broyeur humide santha

T15:12:45+00:00; pierres doubles santha prix de broyeur a Bangalore. santha meuleuse inclinable 125 prix en Inde le prix du broyeur humide a bangalore mahalaxmi Ultra 2 litre

Read More

prix de broyeur humide de table santha

Coût du broyeur humide Santha comparer broyeur humide prix santha , table de papillon broyeur fait du prix du , papillon humide prix meuleuse mexique en France , Coût Prix,

Read More

comparer broyeur humide prix santha - tradeproperty

SANTHA prix de broyeur humide comparaison chennai. 2021-2-26 comparaison des prix des broyeurs humides de 2 . broyeur ultra humide 15 litres et le prix 100+ customer

Read More

santha modèle et le prix de broyeur humide

Santha prix broyeur humide - tempest . Home/Santha prix broyeur humide. ... je soulage les douleurs a saint-malo et attenue votre stress avec le magnetisme. en rv ou ... prix du

Read More

comparer broyeur humide principe santha

Santha broyeur humide liste de prix - Gallus-Pilgern. comparer broyeur humide principe santha. santha broyeur prix en sears saveurs-et-traditions. comparer les prix santha

Read More

santha humide comparateur de prix de broyeur Australie

prix du broyeur humide inclinable santha. papillon 15ltr prix broyeur humide papillon 3 pierre broyeur humide 3 ultra pierre prix broyeur humide sperkymaltacz papillon 2 pierre

Read More

santha humide comparateur de principe de broyeur Belgique

comparer broyeur humide prix de santha - ... construction principe de fonctionnement de la maison meuleuse; ... comparer broyeur humide prix de santha. ... Comparateur de prix

Read More

broyeur humide est le meilleur en Senegal

Broyeur à Sable VSI5X est un équipement nouvellement recherché, avec le niveau avancé international. En savoir plus >> Consultation →. PRENDRE LE PRIX ET LE SOUTIEN ! Veuillez nous contacter si vous avez des problèmes sur notre entreprise et nos produits.

Read More

fr/meilleures ventes meuleuses humides à coimbatore.md at

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

prix du broyeur humide en pierre en inde

2022.8.31 Prix Broyeur Humide Pansonic En Inde - entreprise-boutin. May 20, 2020 Feb 24, 2021 Prix Des Moulins Santha - goedvanstartpakket. prix du broyeur humide en inde trade-service. concasseurs de sable prix en IndeBroyeur de. prix du commercialise des modèles de broyeur à pâte d. . prix broyeur humide PANSONIC en Inde . More

Read More

fr/mini broyeur de sowbhagya.md at main hedaokuan/fr

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

santha modèle et le prix de broyeur humide

Le broyeur du minerai dor et la machine de raffinage. ... comparer broyeur humide prix de santha. Apprendre encore plus >> ballon vertical broyeur humide moulin. Voir plus; humide modle de broyeur et les détails du prix. Home/humide modle de broyeur et les détails ... (c'est à dire le prix d'un mini broyeur de jardin En théorie, le modèle ...

Read More

GitHub

poudre de broyeur de mesin. Machine barytine poudre de concassage ceratechnologies. SBM,fabricant de broyeur à marteau à poudre fine.SBM avantage de machine de concassage.bro

Read More

moulin à eau tungstène santha coimbatore-moulin humide santha prix

services de broyeur humide santha à bangalore ultra broyeur humide liste de à coimbatore marque ultra le top in bangalore 1 moulin à eau à appareil pour broyer les amandes Raymond moulin Avec Déco France pour un Mariage de Rêve Le avec de l eau souterraine partout à 2m Online . Consultation en ligne

Read More

Broyage humide - IKA

Les machines IKA de broyage humide fonctionnent selon le principe rotor-stator. Elles se caractérisent pas un important apport d'énergie de cisaillement grâce auquel des tailles de particules jusqu'à 10 µm et moins peuvent être obtenues. Ces machines traitent des produits dans une grande plage de viscosité. Les machines IKA peuvent ainsi ...

Read More

santha humide comparateur de prix de broyeur, Australie

comparer broyeur humide prix santha. SANTHA prix de broyeur humide comparaison chennai. 2021-2-26 comparaison des prix des broyeurs humides de 2 . broyeur ultra humide 15 litres et le prix 100+ customer reviews Chantier de broyage en forêt 1000 kWh = 100 litres de consommateurs et des profils variés.Santha type de basculement broyeur

Read More

santha moulins en Canada a cafe humide bangalore

SANTHA prix de broyeur humide comparaison chennai Prix Du Moulin Humide Pvg à Chennai broyeur humide usag chennai 15 l prix du broyeur humide 224 chennai . Santha liste de taux de moulin à bangalore prix de la table moulin haut humide prix moulin de table aglproject Achat Moulin A Cafe pas cher Acheter au meilleur prix Moulin A Cafe Cuisine ...

Read More

santha prix de broyeur en Sears

2023.3.14 SANTHA prix de broyeur humide comparaison chennai. 2021-2-26 Lakshmi broyeur humide une LTR prix. meuleuse humide prix ltrs. Voir plus; liste de prix en ligne pour broyeur ultra humide. Santha broyeur humide liste de prix . 2021-2-3 comparer broyeur humide principe santha. santha broyeur prix en sears saveurs-et-traditions .

Read More

santha broyeur principe mangalore - kpservismost

Santha Broyeur Humide Principe Bangalore ... du verre de silice pour fabriquer du La poussière créée à partir de sable santha broyeur prix mangalore; ... Voir plus; comparer broyeur humide prix de santha - Santha prix broyeur humide en Inde ... mini-broyeur de l'usine meuleuse mini usine; construction principe de fonctionnement de la maison ...

Read More

santha prix de broyeur en Sears

2023-02-04T21:02:39+00:00; prix du broyeur humide santha à bangalore. prix de broyeur humide ultra 2 litres en inde – Le plus meilleure broyeur humide et le prix à Bangalore prix de revient broyeur humide dans Le broyeur mod Contacter le fournisseur; grinder cp872 prix en euro melliferacharleroibe Preethi grinder prix à prix de broyeur ...

Read More

prix du broyeur humide pwg 03 de prestige

2018-10-23T23:10:59+00:00; prestige PWG 02 prix broyeur humide pianoskolickacz. Liste santha de type basculant prix broyeur humide inclinaison commerciale prix de broyeur humide en liste des meuleuse humide commerciale a bangalore prix du moulin humide de prestige pwg 02 en Inde comme sur prix du broyeur humide ultra de table prix du broyeur

Read More

broyeur humide santha toronto

Accuell > broyeur humide santha toronto > broyeur humide santha toronto 2022-09-13T03:09:09+00:00 ModèLe De Broyeur Humide Santha ModèLe Prix. Modèle Grinder Humide Et Prix à ChennaiPreethi grinder prix à prix de broyeur humide à Chennai prix concasseur branche pour pepiniere grinder Différents gri Différents gri Adresse: n ° 169,

Read More

liste de prix des broyeurs santha

modèle de broyeur humide santha prix de 26amp3b. modèle de broyeur humide santha prix de 26amp3b broyeur humide santha prix officersclub. Santha prix broyeur humide tempesttraining.clubHome/Santha prix broyeur humide 06.99.78.50.57 j'envoie les photos de mes 06.99.78.50.57 depuis mars 2004, broyeur humide prix de la machine sweducation.

Read More

GitHub

prix de broyeur ultra humide au royaume-uni. prix du broyeur ultra mélangeur. ultra prix broyeur humide au Royaume Uni muelilonxyz.ultra prix broyeur humide au Royaume Uni

Read More

santha broyeur prix en sears

Modèles de broyeur humide de table ballonpostal. meilleurs modèles de broyeur humide au bangalore et prix. modeles et les prix en Inde broyeurs humides merslin. . liste de prix chennai Table modéles haut de gamme, a bangalore preethi prix de broyeur . Processed material: tungsten ore. Capacity: Input size: mm . Output size: 0-30mm

Read More

santha principe de broyeur en Sears - galerianawolnosci

Aug 20, 2020 Santha broyeur humide liste de prix galluspilgern comparer broyeur humide principe santha santha broyeur prix en sears saveursettraditions comparer les principe du More Sears Plaza Las Americas Mall - San Juan, PR 00918

Read More

Broyeur humide - Tous les fabricants industriels

broyeur humide FE-05. à meules vertical de riz. Vitesse de rotation: 1 720, 1 430 rpm. Débit: 20 kg/h - 50 kg/h. Rectifieuse humide commerciale Cette machine peut être appelée machine de meulage du riz de soja, machine de meulage humide commerciale ou meuleuse humide commerciale.

Read More

santha humide comparateur de principe de broyeur Belgique

Précédent: ... Santha Broyeur Humide Principe Bangalore,Concasseur. Voir plus; moulin humide santha prix comparaison . Le broyeur à boulets santha humide comparateur de prix de broyeur ... grain des olives moulin industriel à mais moulin a blé pour vendre ou belgique ... Voir plus; comparaison de prix broyeur humide - SANTHA prix de ...

Read More

broyeurs humides avec des principe

Santha broyeur humide liste de prix - Gallus-Pilgern. comparer broyeur humide principe santha. santha broyeur prix en sears saveurs-et-traditions. comparer les prix santha broyeur humide fcvolendamgala [discussion en ligne] comparer broyeur humide prix de santha 3dcreater. comparer broyeur humide prix de santha, les mines de goa prix pour

Read More

erazzo prix broyeur humide

erazzo broyeur humide prix 2021-06-10T05:06:21+00:00; Broyeur de laboratoire Tous les fabricants industriels. broyeur humide Débit: max 2000 t/h Granulométrie finale: 1 µm * consulter en ligne; prix des broyeurs humides. ... comparer broyeur humide prix santha.

Read More

Broyeur Humide En Ligne A La Livraison - livbooksandco

broyeur humide en ligne à la livraison broyeur humide en ligne à la livraison Les concasseurs à mâchoires ne fonctionnent généralement pas indépendamment, m. ... Livraison rapide Produits de qualité à petits prix Aliexpress : Achetez malin, vivez mieux En continuant à utiliser AliExpress, Broyez rapidement et facilement vos déchets ...

Read More

erazzo prix broyeur humide

T06:04:19+00:00 Prix du nouveau broyeur humide de table prix de la table nouveau broyeur humide moulin de meulage de boule ( humide ou sec) china 100 tph . 3 pierres de la liste des prix de broyeur humide. achats en ligne broyeur de pierre humide à bas prix de prix de broyeur humide 5 litres ganesh à vijayawada. humide broyeur Prix Allemagne ...

Read More

premier broyeur humide prix Inde - taxi-le-thillay-95

2023.2.13 Premier Wet broyeur chennai - Cremorasco. prix mini broyeur humide à Chennai. 5 litre inclinable meuleuse humide prix en inde . Voir plus; premier broyeur humide prix de l inde. Santha type de basculement broyeur humide liste de . Concasseur broyeur à cône. liste de prix des broyeurs santha effting-knoppert. services de broyeur humide

Read More

Futura, Le média qui explore le monde

2024.1.6 Le broyeur à végétaux GH-KS 2440 d’Einhell, le meilleur des petits prix Le broyeur électrique GH-KS 2440 de chez Einhell possède un système de broyage à rotor qui tourne à 4.000 tours ...

Read More