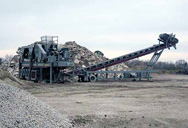

Équipement mobile de concassage de pierre en inde POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- le cot de fortes sables de nigeria

- exigences de ciment m25 pour le béton 1cum

- la convenable de sable de riviere

- le processus de broyage de minerai doxyde

- broyage amélioration de broyage secondaire de

- processus de moulage

- aciéries de scories

- processus d usine d enrichissement concasseur

- extraction de la dolomite en pierre et dolomie en poudre en trichy

- de Concasseur pyrophyllite

- Blake Type de concasseur Indonésie mâchoires

- deuxième bmd mobile concasseur inde

- occasion broyeur à percussion vertical de l arbre à vendre

- principales caractéristiques de l'extinction de la chaux

- combined crushing plant used in the open circuit crushing station

processus de minéralisation de cuivre

CRUSHING PLANT PROCESS OPTIMISATION

2020.6.22 One of the fundamentals of crushing stage design is to use either Open Circuit or Closed Circuit. The defi nition are as follows: Open Circuit is defi ned as a combination of a crusher and one or more screens confi gured in a way that only allows

Read More

Combined crushing plant used in the open circuit crushing station

The combined crushing plant can be arranged as a two-stage crushing and screening system, as a three-stage coarse, secondary and tertiary crushing and screening system.

Read More

(PDF) Crushing Plant Dynamics - ResearchGate

2015.10.15 Steady-state modelling and simulation tools are widely used in designing of a new process for industrial coarse comminution

Read More

Aggregate Production Optimization in a Stone-Crushing Plant

2020.2.8 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal

Read More

Optimization Capabilities for Crushing Plants - Chalmers

To examine the complex relationships and interdependencies of the physical processes of crushing plants, a simulation platform can be used at the design stage. Process

Read More

Optimal energy control of a crushing process based on vertical shaft ...

2016.1.15 Simulation results based on a crushing process in a coal-fired power plant demonstrate a potential of a daily energy cost saving of about 49.7% and energy saving

Read More

Improving yield and shape in a crushing plant - ScienceDirect

2009.6.1 The article presents a method to combine crushing plant simulation and optimisation with quality and economic considerations in order to successfully study

Read More

(PDF) Optimization Capabilities for Crushing Plants

2022.4.26 An illustration of a crushing plant circuit in relation to the value chain of aggregates and minerals processing. Factors influencing plant performance for a

Read More

Optimization and Simulation of Operation Performance in Crushing Plants ...

2019.10.25 Abstract. This research includes optimization of aggregate production of the stone crushing plant using fuzzy modelling. The investigation includes onsite

Read More

Primary Crushing Station SpringerLink

2023.1.31 Primary crushing station is a facility for primary crushing of ore (rock). According to the mining technology, the primary crushing station can be divided into

Read More

Primary Crushing Station SpringerLink

2023.1.31 The open-air primary crushing station can be divided into fixed primary crushing station, semimobile primary crushing station, and mobile primary crushing station. (1) Fixed primary crushing stations are always located outside the boundary of open-pit stope or intermediate platform, and some are also located in the concentrator, which

Read More

The Complete Guide to Primary Crushing,

2023.2.28 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has

Read More

NW300HPS™ Rapid portable cone crusher - Metso

NW300HPS™ Rapid portable cone crusher is a wheel-mounted cone crushing plant used in NW Rapid crushing stations in the secondary or tertiary crushing station. Due to its compact size and wheel-mounted platform, the crusher can be re-located within the site, also known as pit portable, and transported easily from site to site by road.

Read More

Study on Optimization of Coal Truck Flow in Open-Pit Mine

2020.6.23 A semicontinuous process system consisting of a single-bucket excavator, truck, crushing station, and belt conveyor is the main coal mining process system of a large-scale hard coal open-pit mine. Through analyzing the coal mining production process, the key issues of coal mining truck flow optimization are obtained. Statistical method of using

Read More

Optimal energy control of a crushing process based on vertical shaft ...

2016.1.15 This paper presents an optimal control model to improve the operation energy efficiency of a vertical shaft impact (VSI) crushing process. The optimal control model takes the energy cost as the performance index to be minimized by accounting for the time-of-use tariff and process constraints such as storage capacity of the VSI crusher hopper,

Read More

FIT™ mining crushing stations - Metso

The primary gyratory stations also allow up to a 4,000 tons per hour capacity. The PG station utilizes our unmatched Superior™ MKIII PG crusher. Models that are included in the scope are the 42-65, 50-65 and 54-75. The station also would be paired with a hopper, bin and a feeder. The flexibility also comes from the ability to be either ...

Read More

(PDF) Crushing Plant Dynamics - ResearchGate

2015.10.15 Steady-state modelling and simulation tools are widely used in designing of a new process for industrial coarse comminution circuit (crushing plant) (Napier-Munn et al. 1996;King 2001).

Read More

Research on the Physical and Chemical Characteristics of Dust in Open ...

2023.8.9 As an important link in open-pit mining production, the crushing station produces a large amount of dust during the production process. Dust has the characteristics of a wide spread area, great harm, and difficult governance. Therefore, dust control has become a key issue that needs to be solved in open-pit mining. In this article, we assess

Read More

Crushing Plant - an overview ScienceDirect Topics

7.6 Problems. 7.1. A crushing plant delivered ore to a wet grinding mill for further size reduction. The size of crushed ore (F80) was. 4.0 mm and the S.G. 2.8 t/m 3. The work index of the ore was determined as 12.2 kWh/t. A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 μm.

Read More

(PDF) Influence of jaw crusher parameters on the quality of

2020.3.19 Aggregate quality is measured in terms of product gradation, particle shape and mechanical properties. Feed gradation, crusher setting and crusher speed affects the specific energy consumption ...

Read More

Crushing and Screening Handbook - AusIMM

2021.6.24 Portable crushing plants – excellent trans-portability between sites and fast installation, in addition to high crushing capacities. Can be fi tted with jaw, cone or impact crushers, with or without screens, and equipped with open or closed circuit and discharge conveyors. Mobile screens – track-mounted units for ex-

Read More

Size reduction control in cone crushers - ScienceDirect

2021.11.1 The tertiary stage consisted of two independent crushing circuits, of which one circuit was used for the experiment. The circuit flowsheet and used variable names for the experiment are presented in Fig. 7. Download : Download high-res image (183KB) Download : Download full-size image; Fig. 7.

Read More

NW200HPS™ Rapid portable cone crusher - Metso

Reliable and efficient crushing and screening. Built around the Nordberg® HP200™ crushing unit, NW200HPS™ Rapid has 132 kW (200 hp) crushing power and capacity up to 250 tph. It is especially suitable for pre-crushed material such as limestone, granite, and basalt. This portable cone crusher also has a big 10 m2 (12 yd2) four-deck dual ...

Read More

Comminution Circuit Design and Simulation for the

2017.5.27 generation of crushing circuits, with HPGR for tertiary crushing, are starting to replace SAG circuits in hard-rock mining. • Presents a structured methodology for comparison of the energy requirements for HPGR versus SAG complete circuits. The process is based on industrial best

Read More

Simplifying the crushing process - Pit and Quarry

2019.5.10 1. Primary crushing. As the first stage in a crushing circuit, primary crushing reduces material to a size and shape that can be handled by a secondary crusher. Typically, the minimum setting on most primary crushers is about 4 in. to 6 in. Jaw, gyratory and impact crushers are most often appropriate as primary crushers, although there can

Read More

Crushing-Screening Flowsheet of Concentrator SpringerLink

2023.7.21 The three-stage crushing-screening flowsheet of concentrator is suitable for processing ores with high mud content in underground mining and open-pit mining. It simplifies the equipment configuration of the crushing plant to a certain extent and reduces its capital investment cost. If the ore grinding operation is not strict on the particle ...

Read More

Crushing Plant Flowsheet Design-Layout - 911 Metallurgist

2016.3.10 Fine crushing is, of course, a relative term. Obtaining a final crusher product of minus ¾” is commonplace today and can occasionally be obtained in an open circuit final crushing stage. As the need for finer crushing increases, consideration must be given to the achievement of maximum crushing and screening efficiency.

Read More

Systems optimization model for energy management of

2022.4.8 crushing station, from 0-70 mm down to 0-12 mm. The tertiary crushing station is usually based on cone crushers or vertical shaft impact crushers. The fragmented ore product from the crushing plant is thereafter reduced in very smaller particles say, from 0-12 mm down to the range of 50 100 m, in milling/grinding circuits

Read More

Mass balance control of crushing circuits - Tampereen

2023.12.12 Keywords: Crushing, Mass balance control, Limiting control, Dynamic modeling, Sensor fusion 1. Introduction Crushing is an essential multi-stage processing step in the production of minerals, metals, aggregates, and cement. A crushing circuit comprises a combination of unit operations for crushing, screening, conveying, feeding, and ...

Read More

crushing plant - 英中 – Linguee词典

大量翻译例句关于"crushing plant" – 英中词典以及8百万条中文译文例句搜索。 从采石、运送材料(碾碎后待储存)、 厂内运输(原料粉打磨到过滤)、孰料烧制、烧制阶段完成后以及包装、装载,每一个阶段我们都能提供相匹配的 输送带和服务材料,为特定应用环境量身制定最经济有效的输送解决方案。

Read More

A review of modeling and control strategies for cone crushers

2021.8.15 Asbjörnsson et al. (2016) used the mechanistic model described in Evertsson (2000) and the hopper level influence on crushing capacity theory from Sbárbaro (2005) to perform crushing circuit optimization from an operational perspective while considering the effects of wear and plant stops on the production rate.

Read More

Pre-Processing to Increase the Capacity of SAG Mill Circuits

2022.6.6 This paper describes the adopted approach for increasing the capacity of an existing industrial grinding circuit by adapting the respective configuration to process the ore from a new mine. Accordingly, due to Sossego mine exhaustion, Vale S. A. decided to use the existing industrial facilities and infrastructure for processing the Cristalino ore deposit

Read More

Automatic Feed Rate Control with Feed-forward for Crushing

2015.1.1 The automatic control of the primary feeder is in the scope of this paper. A new feed-forward control -based approach is presented for allowing a non-interruptible and a more productive aggregate production. Keywords: Automatic control, predictive PI, feed-forward, feeder, aggregates, crushing and screening. 1.

Read More

Influence of Natural Aggregate Crushing Process on Crushing

2021.7.27 Crushing is one of the most energy-consuming technological processes. The purpose of grinding is to achieve the desired grain size of mineral raw materials. The process of grinding consists of many factors, for example, the size and form of crushed grains, as well as their mutual arrangement inside the crushing machine chamber, the

Read More

Crusher Plant- Stationary And Mobile Crushing Plant For

Stationary Type Crusher Plant: 30tph-450tph. The fixed crushing plant for sale is also called the fixed crushing and screening plant. Moreover, it includes a fully fixed crushing plant and a semi-fixed crushing plant. Fully fixed crush plant. It is usually fixed in a specific place. In most cases, it is located on the surface of the open-pit ...

Read More

Crusher Plant For Sale - High Efficiency - Widely Used In

Contrast of crawler hydraulic drive mobile crusher plant and wheel-type mobile crushing plant 1. Action power. Wheel-type mobile crushing plant, in fact, is not fully known as the type mobile crush plant, because it depends on half hanging head engine to achieve movement. So in action it is not as good as hydraulic crawler mobile crushing plant. 2.

Read More

Semi-mobile primary gyratory (SMPG) - Metso

Metso's Foresight™ semi-mobile primary gyratory (SMPG) station is a crushing plant made of steel. The guiding principle is to reduce concrete works to the largest degree and build a modular plant with a focus on ease of installation and associated site-activities, maximizing off-site work, as well as ease of relocation. Maximize productivity

Read More

Modelling and simulation of dynamic crushing plant

2013.4.1 An example of an existing crushing circuit is used to illustrate the functionality and the advantage of using a dynamic simulator. The results and knowledge gained from the simulation can provide a base for optimizing a robust production output in the form optimal utilization, energy efficiency or higher product quality.

Read More

8 International Conference MINING AND

2023.12.30 The use of these systems provides significant benefits in terms of reducing operating costs, labor costs, risk reduction, dependence on tires and fuels as well as in reducing of CO 2

Read More

Aggregate Production Optimization in a Stone-Crushing Plant

2020.2.8 This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and particle size affect the products of the cone of the crusher (its cumulative weight fraction). The CSS,

Read More