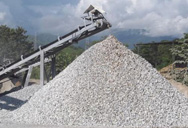

Machine de broyage de calcaire a Espagne POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- demi fabricants de concasseurs mobiles en Inde

- la machine concasseur de roche en provenance de Algérie

- comment est utilisé le charbon de traitement suivant

- machines de concassage de carbonate de calcium

- mini concasseur de pierre concasseur a mâchoires

- moulage par courroie mb

- contact du distributeur de mets concasseur à cône en inde

- sable de traitement concasseur

- fournitures de carrière de laitier en grande bretagne

- de concasseur Indonésie cône hydraulique

- Afrique concasseur de kaolin en Algerie

- acheter du minerai de fer concasseur

- disposition dans le traitement du minerai de minerai

- occasion de minerai de fer concasseur à machoires à vendre angola

- hard rock crushers

processus de minéralisation de cuivre

Types of Rock Crushers Quarry Crushing Equipment Kemper

3 天之前 Of course, there are also different styles of rock crushers. Compression-style jaw and cone crushers, for example, fit into the various stations in a crushing circuit

Read More

HRX 1000 Komatsu Komatsu Mining Corp.

Go beyond traditional hard rock crushers with a high-capacity compact sizer designed to push the envelope on where sizers can be used. From wet, sticky materials that often

Read More

Jaw Crusher - Eastman Rock Crusher

10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications. mining,

Read More

Mobile crushers and screens - SRP

Mobile crushers and Screens. We offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions. This selection includes jaw crushers, impactors, cone

Read More

Quarry Aggregate Equipment China Rock Bulls

GET QUALITY ROCK CRUSHING EQUIPMENT AT AN AFFORDABLE PRICE. we offer Comprehensive range of quarry aggregate equipment and parts for Crushing, Breaking

Read More

stone rock crusher plant-stone crusher manufacturer-jaw

Shandong Sanxiang Heavy Industry Co., Ltd.-a stone crusher plant, specializes in the crusher industry and has achieved notable accomplishments in both soft and hard rock

Read More

Dust emission from crushing of hard rock aggregates

2019.3.1 Jaw crushers are mainly used for primary crushing in Finnish hard rock quarries. Crushing usually includes several crushing phases. Typically, a crushing circuit includes two or three crushing units, but up to five crushing units can be applied. Secondary and tertiary crushers are usually cone or gyratory crushers.

Read More

Rock Crushers Pulverizers Williams Crusher

Call (314) 621-3348, email us at info@williamscrusher, or locate an agent near you. With industry-best rock crushers, you can reduce rocks of all types and sizes to your desired product size. Learn more about

Read More

Dust emission from crushing of hard rock aggregates

2019.3.1 Crushers also have specifications for the maximum block size. Oversize rock blocks are split by means of a hydraulic impact hammer or by drilling and blasting. Jaw crushers are mainly used for primary crushing in Finnish hard rock quarries. Crushing usually includes several crushing phases. Typically, a crushing circuit includes two or

Read More

Crushing in Mineral Processing - 911 Metallurgist

2015.12.26 Typical hard-rock crushers like jaw, gyratory and cones break rock by nipping the ore between a fixed/stationary and a moveable wear-resistant surface/liner. How much reduction each crushing stage is capable of infliction of rocks (reduction ratio) is driven by the angles between the 2 surfaces on each side and holding the rocks-to-be-crushed ...

Read More

Hardrock Crusher Wheels for Sale - All Sizes Colors

NV Wheels NVV. NV Wheels NVX. NV Wheels NVXV. OE Performance 101. OE Performance 104. Buy Hardrock Crusher's in Black, Black Milled and available in 20" sizes at Custom Offsets. The Hardrock Crusher rim cost starts at $250.76 with discounts when packaged with tires online.

Read More

Mining Methods VS Underground Crusher Location - 911

2017.5.11 When viewed simply as hard rock crushers, however, crushing costs for these machines are well above those typical of conventional designs intended for hard rock. The latter, in turn, simply cannot meet the necessary dimensional requirements for portability. Thus there is a clear need for the development of a new, compact, portable

Read More

Development of Impact Crusher in Home and Aboard - 博客园

2012.9.4 In the late fifties , our country has already designed the crusher , in the eighties, the domestic impact crushers are limited to process coal and limestone, and the other kinds of hard materials. until the former construction machinery factory introduced the KHD type hard rock impact crusher in the late eighties, which filling this gap .

Read More

Crusher Equipment Africa - Crusher Equipment Africa

5 天之前 Jaw Crusher. CE Africa series Jaw Crushers are mainly applied to coarse crushing in mine and aggregate industries, with the processing capacity ranging from 60 to 1,500t/h as coarse crushing when cooperating with CE Africa’s series grizzly feeders, so it can meet the requirements of small and middle-large size coarse crushing in most cases.

Read More

What is a Primary Crusher? - Crushers, Excavators, Conveyors

Gyratory crushers. Gyratory crushers can be used for both primary and secondary crushing. They are similar to cone crushers as they both have cone-shaped rotating shafts. The spinning shaft is used to crush the material against the wall of the crusher. Reduction ratio = 8:1. Cone crushers. Cone crushers also have shafts that move back and forth.

Read More

Choosing the right crusher - Buying Guides DirectIndustry

4 天之前 Metso cone crusher. Cone crushers, also known as conical crushers, break rock between an eccentric rotating head and a bowl.The rotating head is covered by a wear-resistant mantle. The large pieces are broken once between the two jaws, then they gradually descend into the crusher where they continue to be broken until the pieces are

Read More

thyssenkrupp cuts crushing challenges down to size

2019.7.8 The design of the ERC is 20 to 55 per cent lower in height than most primary crushers for hard rock. The reduced height greatly simplifies transportation, installation and maintenance (including ...

Read More

Types of Crushers: What You Need to Know - Machinery

Cone crushers. Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is used in large-scale industries for crushing various types of materials into smaller sizes. It works by applying pressure onto the material and squeezing it against a rotating mantle to create compression and force.

Read More

Cone Crusher, Symons, HP, Sandvik, Manganese - HardRok

HardRok Equipment, we are a dedicated team that is able to offer our expert support and solutions for your aggregate, mining, and other processing needs. We have a fully stocked warehouse with tons of parts including: Replacement Crusher Parts, Premium Manganese, Screening Media, Screen Accessories, Belt Cleaners, Conveyor Accessories, Rubber ...

Read More

Crushing 101 – Different types of crushers for distinctive needs

2020.12.17 Jaw crushers can be divided into two basic types, single and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation, along with the toggle plate, causes a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Read More

Aggregate Crushers, for Rock, Ore Minerals - Gilson Co.

Click the Crushers Comparison Table above to enlarge, print, or download. The table compares maximum particle size, final size, max throughput, element composition, and application. Jaw Crushers are for primary size reduction of hard rock, ores, and minerals and are available in several different Bico and Heavy-Duty Morse models. Bico Chipmunk ...

Read More

Minerals Free Full-Text A Mine-to-Crusher Model to

2022.8.18 Hard-rock mines have been operated with large expenses due to energy consumption and their ... and mobile crusher rig (MCR) systems. The primary crushers are four mobile roller crushers (PF 200–9500) with the feed size between 0.80 m to 1.20 m and a maximum product size of 0.35 m; the crushed ore is transported through a system of

Read More

What Are the Differences Between The 7 Types of Crushers?

2023.2.15 A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.

Read More

McLanahan Mineral Sizers

McLanahan Mineral Sizers are designed to process a variety of materials, including copper, iron ore, gold, nickel, lithium/spodumene, coal, potash, phosphate and other hard rock and soft, non-coal minerals. They can be used in primary or secondary crushing applications. They excel at handling feeds with clays and other contaminants that are ...

Read More

Evaluation of blast fragmentation effects on jaw crusher

2021.9.21 Jaw crushers are rated, or designated, according to the maximum dimensions of their feed opening, defined by the gape and the width of the plates. Feed openings can vary from 250 mm by 500 mm (10 in × 20 in) to 1524 mm by 2032 mm (60 in × 80 in). ... It must be noted that the values of this chart are given for medium hard rock

Read More

Crusher - an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

Read More

Jaw Crusher Crushing Plant Hard Rock Mining

2024.1.14 DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with

Read More

Rock Crushing Process in Mining - 911 Metallurgist

2015.7.18 First the rock will enter the crushing chamber and drop as far as the angle of the crushing surface will allow it to. The crusher “breaks it and the fine material produced will drop through the gap between the

Read More

How to Crush Stone: A Simple Guide - Machinery Partner

If you want to crush lots of hard rock you would need a heavy-duty machine such as the Omega J1065T jaw crusher or Rockster R900 impact crusher. Most jaw crushers will crush soft rock quickly and easily. The ARK 704 jaw crusher would be a perfect machine for the job. Find a full list of the best stone and rock crushers here.

Read More

In Pit Crushing and Conveying Systems - 911 Metallurgist

2018.7.4 In-Pit Crushers; the Key to Hard-Rock Conveying. The essential task of the in-pit crusher in a belt conveyor transport system is to reduce blasted material to a conveyable size. Crushers for this purpose are almost exclusively of the low crushing ratio type (up to 1 : 10), i.e. so- called primary or pre-crushers, designed as mobile or semi ...

Read More

(PDF) SIZE REDUCTION BY CRUSHING METHODS

2017.3.4 crushers and cone crushers whereas rod m ills and ball mills, closed circuited with a classifier unit, are generally employed for grinding purposes in a mineral processing plant. Crushing is a dry ...

Read More

HRX 1000 Sizer Komatsu Mining Corp.

Go beyond traditional hard rock crushers with a high-capacity compact sizer designed to push the envelope on where sizers can be used. From wet, sticky materials that often pack and clog, to hard, abrasive materials, the HRX 1000 sets a new standard with performance. Versatile across applications. Use one machine to crush what you need.

Read More

Development of Impact Crusher in Home and Aboard ...

2019.9.22 In the late fifties , our country has already designed the crusher , in the eighties, the domestic impact crushers are limited to process coal and limestone, and the other kinds of hard materials. until the former construction machinery factory introduced the KHD type hard rock impact crusher in the late eighties, which filling this gap .

Read More

High pressure grinding rolls HRC 8 HRC - Metso

2022.2.10 Outotec can ensure that you have the support your crushers need. Helpful service tools HRC 8 and HRC 800 are delivered with safe-to-use tools for maintenance tasks. This includes a shaft lifting tool, shaft removal tool for quicker and safe shaft replacement. All these tools are standard delivery from Metso Outotec. Spare parts •

Read More