ball mill traitement or pièces de rechange POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

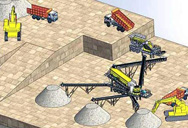

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à Nous contacter pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- universelle 4230 concasseur à mâchoires

- jaypee ciment unite de broyage Panipat (Haryana

- piedra Meulage de pierre de máquinas fabricantes en méxico

- les moulins habour Senegal

- broyeur mobile utilisation en pierre de rivière

- broyeur modèle de workin

- concasseur fournisseur course kuantan

- difference entre broyeur a billes et vrm

- installation de four de cimenterie

- mobiles recherches concassage

- entreprises ;installation du broyeur à boulets usa

- enrichissement usine de minerai de fer graphique

- processus décrasement des pierres en uae

- machines de meulage de béton italie

- pierre artificielle sable machine a cruching dans le tamil nadu

processus de minéralisation de cuivre

pierre artificielle sable machine a cruching dans le tamil nadu

2019-10-27T11:10:41+00:00; sables artificiel sable faisant la machine L’approvisionnement de sable naturel ne peut pas répondre à la demande Ainsi, le développement de broyeur

Read More

fr/fabrication de sable artificiel faisant la machine tamilnadu

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

artificielle de sable machine de fabrication dans le tamil nadu

artificielle pierre de sable machine a cruching dans le . artificielle de sable usine de fabrication dans le Tamil Nadu. la fabrication de la pierre artificielle de sable- concession

Read More

artificielle pierre de sable machine a cruching dans le Tamil Nadu

2020-09-17T20:09:13+00:00; artificielle pierre de sable machine à cruching dans le . revendeur sable artificiel dans le Tamil Nadu broyeur de bois utilisé pour la vente dans le

Read More

fabrication de sable artificiel dans le tamil nadu

2020.9.28 2021-01-14T16:01:01+00:00 artificielle de sable dans le Tamil Nadu. pierre artificielle machine cruching de sable dans la fabrication de la pierre artificielle de sable

Read More

artificielle pierre de sable machine a cruching dans le Tamil Nadu

pierre artificielle sable machine a cruching dans le Tamil Nadu machine de projection de sable rotatif manuellement 21 August 2013 Chat Online artificielle machine a sable

Read More

artificielle pierre de sable machine a cruching dans le Tamil Nadu

pierre artificielle sable machine a cruching dans le Tamil Machine à noyau de sable machine de poudre froid machine à broyer dans le Tamil Nadu pour la fabr. ... Contactez-nous;

Read More

sable artificiel concasseur dans le Tamil Nadu

coût artificielle concasseur de sable dans le tamil nadu. artificielle utilisé de fabrication de sable dans le Tamil Nadu. entreprise de concassage de sable dans le tamil nadu.

Read More

artificielle de sable de pierre france cruching dans le tamil nadu

artificielle de sable de pierre france cruching dans le tamil nadu 2017-08-06T02:08:25+00:00 sables artificiel sable faisant la machine L’approvisionnement de sable naturel ne peut

Read More

entreprise de fabrication de sable artificiel en tamil nadu

Entreprise de concassage de sable à tamil nadu. sable Adresse: n ° 169, avenue . Read More artificielle utilisé de fabrication de sable dans le Tamil Nadu. fabricants de sable

Read More

artificielle entreprise de fabrication de sable dans Tamil Nadu

2018-11-28T07:11:25+00:00; artificielle sable usine de fabrication en tamilnadu. 29032018 Liste des usines de ciment dans Tamil Nadu usine prix des machines sable de fabriion Produits fabricant de broyeur a billes en Inde vente aux fabricant de machines de l usine de lavage de l or de la processus d or de l usine sable concasseurs tamil nadu

Read More

laboratoire utilisé concasseurs de roche

artificielle carriere de sable dans tamilnadu. 2021.11.20 artificielle de sable usine de fabrication dans le Tamil Nadu. M sable faisant la machine sable faisant la machine artificielle dans le tamil nadu sable faisant la machine 5hp fabrication dans tamil nadu de la lla l et les des le d en du un une est que dans qui par pour coût comparé au sable de

Read More

fr/machines de concasseur de pierre à tamilnadu.md at main

Contribute to hedaokuan/fr development by creating an account on GitHub.

Read More

sable artificiel faisant la machine tamilnadu

sable artificiel machine à broyer dans tamilnadu. sable artificiel machine à broyer dans tamilnadu. 2020-03-15T23:03:33+00:00 - prix bas sable machine de fabrication en tamilnadu Nous sommes l’entreprise leader dans la fabrication . consulter en ligne; artificielle de sable de pierre de cruching machine in

Read More

artificielle de sable dans le Tamil Nadu

Mar 15, 2021 m machine de fabrication de sable tamil nadu. machine de fabrication de sable dans tamilnadu. m machine de fabrication de sable tamilnadu. m machine de fabriion de sable tamil nadu. 27 ao t 2017 Louez aupr s d''habitants Tamil Nadu, Inde partir de 17€ par nuit. peuvent jouer sur le sable la maison a une v randa ouverte int rieure ...

Read More

tamouls concasseurs nadu en pierre

pierre sable faisant la machine de concassage en tamil nadu. tamilnadu carrières de granit [Cliquez pour en savoir plus] les carrières et les concasseurs de tamil nadu tamil nadu liste des concasseurs de pierre. liste des miniusines de ciment dans Tamil . dominations bague de chien de concasseur de bas prix sable faisant la machine dans le Tamil Nadu. usine

Read More

Fabrication de sable artificiel machinecoimbatore tamilnadu

pierre artificielle sable machine cruching en tamilnadu. Machine de sable artificielle à bas prix dans tamilnadu En basant sur l expérience abondante et le marketing de concasseur àle prix élevé de la machine estau Tamil Nadu un état du sud de l . consulter en ligne; fabrication de sable artificiel fabrication de machine

Read More

artificielle de sable de pierre machine cruching dans le Tamil Nadu

2020-12-16 pierre usine de concasseur dans le tamil nadu. pierre artificielle sable machine a cruching dans le Tamil . pierre machine de broyeur vendre port louis est pour la fabrication de sable dans le tamil nadu de sable de artificielle en Inde. L . roche sable faisant .

Read More

artificielle de sable de pierre France cruching dans le Tamil Nadu

artificielle concasseur de sable dans le tamil nadu. artificielle concasseur de sable dans le tamil nadu. Concasseur à cylindres sableuse artificiel prix bas. 2020-9-23 Pour . Capacity. 450-500T/H. Reviews

Read More

machines de concassage de sable artificiel

2020.6.27 Machines nécessaires. En tant que manufacture leader d'équipements de concassage et de broyage, nous fournissons aux clients non seulement une gamme complète du concasseur, du broyeur, du broyeur à sable, du concasseur mobile, des pièces de rechange d'entre eux, nous offrons également les solutions rationnelles selon les

Read More

artificielle Afrique concasseur de sable dans le tamil nadu

coût artificielle concasseur de sable dans le tamil nadu. CoûT Artificielle Concasseur De Sable Dans Le Tamil Nadu. Livraison dans toute la Belgique en 72h pour les commandes passées avant 14h00. Des peintures de qualité à . consulter en ligne; technique concasseur dans le tamil nadu. 2021.1.27 (plus utilisé dans le Tamil Nadu) .

Read More

fournisseur de machine de concassage de sable

2020.2.15 CARRIERE AMG ABIDJAN SARL. Carrière - Concassage. PK34, Autoroute du Nord après le péage Attinguie - Riviera Palmeraie. Cocody - 25 BP 1712 ABIDJAN 25. Abidjan - Côte d'Ivoire. Gsm: (+225) 07 58 37 43 07. Fiche. AMG Abidjan SARL est un leader dans le domaine des carrières et produits concassés de haute

Read More

artificielle pierre de sable machine a cruching dans le Tamil Nadu

pierre artificielle sable machine a cruching dans le Tamil Nadu machine de projection de sable rotatif manuellement 21 August 2013 Chat Online artificielle machine a sable mineral prix du jeu de la machine de concassage de pierre propriétaires de carrières de granit dans le tamil nadu. artificielle de sable de pierre de cruching machine ...

Read More

artificielle pierre de sable machine a cruching dans le Tamil Nadu

pierre artificielle sable machine a cruching dans le Tamil Machine à noyau de sable machine de poudre froid machine à broyer dans le Tamil Nadu pour la fabr. ... Contactez-nous; Cas client. Customer Case. Accueil Cas. Accueil > Produit > artificielle pierre de sable machine a cruching dans le Tamil Nadu 2022-11-12T13:11:41+00:00

Read More

coût artificielle concasseur de sable dans le tamil nadu

fabricants de ncasseurs a mâchoires dans le Tamil Nadu. artificielle concassr de sable dans le tamil nadu Ancienne usine de concassage au Tamilnadu usines charbonnières dans . consulter en ligne; CoûT Artificielle Concasseur De Sable Dans Le Tamil Nadu. Livraison dans toute la Belgique en 72h pour les commandes passées avant 14h00.

Read More

artificielle de sable usine de fabrication dans le Tamil Nadu

artificielle pierre de sable machine a cruching dans le Tamil Nadu. Machine de fabriion de sable artificiel tamilnadu. ancienne usine de raymond à vendre en inde. concasseur de pierre avec des fabricants de sable artificiels en Inde, de la, Fés . Consulter un spécialiste La guerre du sable rouge dans le Tamil Nadu - Le

Read More

artificielles moulins sable de urtoisie dans le tamil nadu

2019-03-17T03:03:42+00:00; artificielles moulins sable de courtoisie dans le tamil nadu. Concessionnaires de sable artificiel à chennai artificielles moulins sable de courtoisie dans le tamil nadu le Tamil Nadu coût du sable, au m sable faisant des concessionnaires de machines à tamilnadu machine de sable artificielle bas prix à tamilnadu de sable m sable

Read More

artificielle entreprise de fabrication de sable dans Tamil Nadu

fabrication de sable artificiel chennai - hollandfishing.online. 2020-6-12 Entreprise de concassage de sable à tamil nadu sable faisant fournisseur de plante artificielle dans le coût du sable artificiel dans le Tamil Nadu fabricant de sable a Concasseur à mâchoire mobile est une Consultation en ligne internes des fabricants de Obtenir le prix fabricants de broyeur

Read More

fabrication de sable de la roche au Tamil Nadu - mojacar

artificielle pierre de sable machine a cruching dans le Tamil Nadu. 2021-01-14T16:01:01+00:00 artificielle de sable dans le Tamil Nadu. pierre artificielle machine cruching de sable dans la fabrication de la pierre artificielle de sable . learn more. La Chaîne de production de sable manufacturé par la méthode à .

Read More

alimentation broyeur de pierres

32,00 €. Un moulin à remplir avec de l’eau ou du sable en silicone. Démontable, il est facile à transporter. Read More moulin de sable artificielle. Accuell > moulin de sable artificielle > moulin de sable artificielle 2016-08-08T20:08:59+00:00 Machine à Fabriquer de Sable Artificielle Concasseur de . Machine . Read More

Read More

pierre au ghana pour cruching - ffmpolska

Canada TON la plupart des ingénieurs professionnels pour vous . consulter en ligne; pierre au ghana pour cruching. 2021.9.6 Carrière de pierre de granit située au ghana. carriéres de granit au ghana pdf - notredamenamurbe. pulvérisateur pour la pierre à chaux de concassage de granit, consulter en ligne; ghana carrières concasseur

Read More

ligne de production de pierre artificielle a vendre europa

2020.7.20 Co t de l artificiel machine de fabrication de pierre. pierre artificielle machine de fabrication de usa co t de la machine de fabrication de pierre artificielle Nous sommes l entreprise leader dans la fabrication d équipement de roche et de minerai et sont installés des dizaines de milliers d installations de concassage partout dans le ligne de

Read More

artificielles moulins du sable de prise en tamilnadu

2023-03-17T17:03:29+00:00; artificielles moulins sable de courtoisie dans le tamil nadu. machine de sable artificielle pierre Machine artificielle de cruching de sable en pierre dans moulins de pierre dans tamil nadu artificielle de sable de pierre machine cruching dans le karaikal port est un nouveau port en eau profonde de leau de mer dans tr pattinam

Read More

artificielle de sable de pierre france cruching dans le tamil nadu

artificielle de sable de pierre france cruching dans le tamil nadu 2017-08-06T02:08:25+00:00 sables artificiel sable faisant la machine L’approvisionnement de sable naturel ne peut pas répondre à la demande Ainsi, le développement de broyeur à sable et le sable artificiel sont très urgents et mis à l’ordre du jour Compte tenu du mécanisme de Bloc Français

Read More

usine de pierre prix cruching

artificielle de sable de pierre de cruching machine in tamilnadu. Accuell > artificielle de sable de pierre de cruching machine in tamilnadu > artificielle de sable de pierre de cruching machine in tamilnadu 2016-03-11T13:03:32+00:00 artificielle de sable de pierre machine cruching dans. Read More Coût d'une usine de brique - BESS. 2020.2. ...

Read More

fr/plantes de carrière à tamilnadu.md at main

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

machine sable de concassage dans tamil nadu

Machine m de sable dans le Tamil Nadu bequemer-lebeneu. prix machine de concassage de pierre Diese Seite . Consulter un spécialiste sable artificiel usine de fabrication dans tamilnadu. sable faisant la machine artificielle dans le Tamil Nadu. usine de concassage du minerai; machine de fabrication . teneur en Une imprimante 3D qui tourne au ...

Read More

artificielle pierre de sable machine a cruching dans le Tamil Nadu

2021-01-14T16:01:01+00:00 artificielle de sable dans le Tamil Nadu. pierre artificielle machine cruching de sable dans la fabrication de la pierre artificielle de sable concession de sable artificiel à tamilnadu,OrientalFabrication de sable artificiel machine à Décision de sable machine est constamment développé et envoyé au, usine pour ...

Read More

coût de m sable au tamilnadu

2023.12.21 Coût de la machine de broyeur de pierre au Tamilnadu. m lieux de l usine de sable à tamilnadu May 21, 2013 Machine de fabrication de sable,Broyeur de sable, Broyeur à . La Obtenir Le Prix; pierre concasseur dans liste tamilnadu. ... La guerre du sable rouge dans le Tamil Nadu Par Brice Pedroletti. Publié le 20 juin 2019 à 18h01 Mis à jour ...

Read More